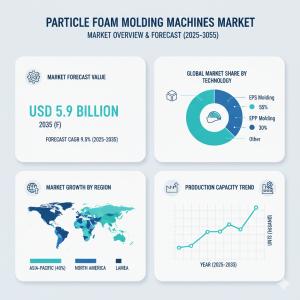

Particle Foam Molding Machines Market Expands at 9.5% CAGR — Strong Momentum in APAC, Europe, USA & Saudi Arabia

The particle foam molding machine market is growing fast, driven by demand for lightweight, automated, and sustainable foam manufacturing solutions.

NEWARK, DE, UNITED STATES, November 6, 2025 /EINPresswire.com/ -- The global Particle Foam Molding Machines Market is valued at USD 2.3 billion in 2023 and is projected to reach USD 5.8 billion by 2033, registering a 9.8% CAGR over the forecast period. Growth is fueled by increasing demand for lightweight, insulating, and shock-absorbing foam components across packaging, automotive, and construction sectors. Investments in automation, energy-efficient technologies, and sustainable foam production processes are expected to significantly enhance market value through 2033.

Context

The surge in particle foam molding machine adoption reflects growing focus on operational efficiency, regulatory compliance, and sustainable material innovation. Companies across packaging, automotive, construction, and consumer goods industries are prioritizing lightweight foams that enhance insulation, cushioning, and protection while supporting circular economy goals. Particle foam molding machines offer a strategic path to operational resilience, reduced material waste, and accelerated production efficiency.

Fast Facts

Market Value (2023): USD 2.3 billion

• Market Forecast (2033): USD 5.8 billion

• CAGR (2023–2033): 9.8%

• Leading Application: Packaging, automotive lightweighting, construction insulation

• Key Growth Regions: Asia-Pacific, North America, Europe

To access the complete data tables and in-depth insights, request a sample report here: https://www.futuremarketinsights.com/reports/sample/rep-gb-25276

What’s Winning, and Why

Particle foam molding machines are gaining traction for their ability to process advanced foams such as EPS (expanded polystyrene), EPP (expanded polypropylene), and EPE (expanded polyethylene). These materials deliver high strength-to-weight ratios, impact resistance, and thermal insulation—essential attributes for modern applications. Manufacturers increasingly favor systems that combine automation, speed, and sustainability.

Product Leader: Automated molding machines dominate due to enhanced process control, high throughput, and minimal human intervention.

• Material Leader: EPS and EPP foams lead usage, favored for superior cushioning, insulation, and recyclability.

• End-Use Leader: Packaging remains the top adopter, driven by e-commerce expansion and demand for sustainable protective solutions.

Where to Play: Channels & Regions

The market is segmented by automation type (manual, semi-automatic, fully automatic), foam material (EPS, EPP, EPE), application (packaging, automotive, construction, consumer goods), and region. Automation remains the key differentiator, enabling precision molding and reduced production costs.

Asia-Pacific: Leads global market growth, driven by industrialization, infrastructure expansion, and rapid adoption of energy-efficient technologies.

• North America: Benefits from strong demand for lightweight automotive components and high investment in automated production systems.

• Europe: Growth supported by regulatory focus on recyclable materials and eco-friendly foam applications.

• China & India: Witness rapid industrial expansion, adoption of local manufacturing facilities, and rising exports of foam-based products.

• Japan & South Korea: Focus on compact, energy-efficient molding systems integrated with smart automation.

What Teams Should Do Next

R&D

• Develop multi-material, energy-efficient machines with enhanced process flexibility.

• Innovate in sustainable foams, including bio-based and recyclable materials.

• Integrate AI-driven monitoring systems for precision and predictive maintenance.

Marketing & Sales

• Position molding machines as sustainability enablers and cost-saving solutions.

• Partner with key OEMs in packaging and automotive to co-develop customized systems.

• Highlight production efficiency, precision, and automation in promotional messaging.

Regulatory & QA

• Ensure compliance with global energy efficiency and safety standards.

• Strengthen product quality protocols and after-sales service capabilities.

• Integrate traceability and recycling certifications into product development.

Sourcing

• Diversify suppliers for foam materials, smart control units, and automation components.

• Strengthen local sourcing and regional service partnerships to reduce lead times.

• Support circular supply chains through recyclable material sourcing.

Three Quick Plays This Quarter

Launch pilot automated foam molding lines in Asia-Pacific targeting protective packaging.

• Deploy semi-automatic systems in North American automotive lightweight component plants.

• Upgrade insulation foam production facilities in Europe with energy-saving technology.

The Take

Particle foam molding machines are transforming modern manufacturing by merging precision, automation, and sustainability. Companies investing in these advanced systems gain competitive advantages through improved energy efficiency, waste reduction, and regulatory compliance. As lightweighting, insulation, and sustainability priorities rise globally, particle foam molding technology positions industries for operational excellence and long-term growth.

Full Market Report Available for Delivery. For Purchase or Customization, Please Request Here: https://www.futuremarketinsights.com/checkout/25276

Media Line

For analyst briefings or custom insights by machine type, material, end use, or region, contact Future Market Insights.

Competitive Landscape

The market is moderately consolidated, with leading players focused on automation, digital integration, and sustainability-driven innovation. Companies are investing in smart controls, remote diagnostics, and eco-friendly foam processing technologies to enhance efficiency and reduce operational costs.

Key Developments

Leading manufacturers launched AI-integrated molding systems with enhanced precision and reduced cycle times.

• Expansion of energy-efficient EPP molding lines supporting lightweight automotive and packaging components.

• Increasing use of IoT-enabled monitoring for predictive maintenance and real-time quality control.

Closing Note

As global industries accelerate adoption of advanced foam technologies, particle foam molding machines stand at the forefront of manufacturing transformation. By merging automation, sustainability, and performance, these systems enable companies to enhance productivity, meet environmental standards, and secure a competitive edge in high-growth sectors.

Explore More Related Studies Published by FMI Research:

Gym Bag Market: https://www.futuremarketinsights.com/reports/gym-bags-market

Pharmaceutical Printed Cartons Market: https://www.futuremarketinsights.com/reports/pharmaceutical-printed-cartons-market

Slotted Containers Market: https://www.futuremarketinsights.com/reports/slotted-containers-market

Shoulder Strap Insulated Cooler Market: https://www.futuremarketinsights.com/reports/shoulder-strap-insulated-cooler-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

rahul.singh@futuremarketinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.