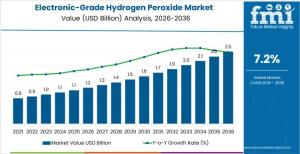

Electronic-Grade Hydrogen Peroxide Market Projected to Reach USD 2.5 Billion by 2036 Amid Advanced Node Transitions

The electronic-grade hydrogen peroxide market is projected to grow from USD 1.2 billion in 2026 to USD 2.5 billion by 2036, at a CAGR of 7.2%.

NEWARK, DE, UNITED STATES, January 19, 2026 /EINPresswire.com/ -- The global electronic-grade hydrogen peroxide (EGHP) market is entering a high-growth phase, with its valuation projected to rise from USD 1.23 billion in 2026 to USD 2.5 billion by 2036. This expansion, representing a compound annual growth rate (CAGR) of 7.2%, is fundamentally driven by the semiconductor industry’s shift toward sub-5nm process nodes and the escalating demand for ultra-high-purity (UHP) cleaning agents.

As semiconductor fabrication moves toward smaller geometries and tighter defect tolerances, EGHP has evolved from a commodity chemical into a yield-critical consumable. The market’s momentum is currently anchored by large-scale fab investments in Asia Pacific, North America, and Europe, where localized supply chains are becoming a strategic priority for industry leaders like Solvay SA, Evonik Industries AG, and Mitsubishi Gas Chemical.

Strategic Market Dynamics: Purity as the Primary Yield Driver

The drive for miniaturization in logic and memory chips has made ultra-pure hydrogen peroxide indispensable. Even trace metallic or organic contamination at parts-per-trillion (ppt) levels can cause catastrophic yield loss in advanced manufacturing.

• Yield Sensitivity: Advanced logic and 3D NAND production require rigorous surface preparation. EGHP is the core oxidizing agent in RCA cleaning and atomic layer etching (ALE) processes.

• Grade Dominance: Semiconductor-grade hydrogen peroxide currently holds a 44% market share, as fabs prioritize tightly controlled chemical specifications to support shrinking node sizes.

• Application Intensity: Wafer cleaning and etching represent the largest application segment, accounting for 40% of demand. The repetitive nature of these steps during fabrication sustains high-volume consumption.

Request For Sample Report | Customize Report | Purchase Full Report -

https://www.futuremarketinsights.com/reports/sample/rep-gb-31485

Regional Growth Insights: Key Markets and CAGR Projections

While established semiconductor hubs continue to scale, geographic regionalization is reshaping the competitive landscape. The following regions and countries are identified as high-growth corridors through 2036:

• China (8.4% CAGR): Leading global growth due to aggressive large-scale investments in domestic memory, logic, and power semiconductor fabs, alongside a strategic push to localize critical electronic chemical supplies.

• Brazil (8.0% CAGR): Emerging as a high-growth market supported by the expansion of electronics assembly, specialty component production, and compound semiconductor processing.

• Europe (7.0% CAGR): Growth is sustained by heavy investment in automotive electronics, sensors, and power semiconductors which require strict purity traceability and long-term supply stability.

• United States (6.9% CAGR): Driven by renewed domestic fab capacity and government-backed initiatives, particularly in advanced logic and memory sectors requiring ultra-clean processing environments.

• Germany (6.8% CAGR): A cornerstone of the European market, focusing on precision manufacturing for industrial automation and automotive semiconductors.

Supply Chain Resilience and Global Competition

Procurement professionals and investors are increasingly focusing on supply security. To mitigate disruption risks, major players are co-locating purification facilities near fab clusters.

Solvay SA and Evonik Industries AG (including its PeroxyChem division) lead the market by emphasizing ultra-low metal impurity levels and robust batch traceability. In Asia, Mitsubishi Gas Chemical and Mitsubishi Chemical Group have optimized their portfolios for compatibility with automated chemical delivery systems (CDS) used in "mega-fabs." Other significant contributors include Arkema SA, OCI Company Ltd., Linde plc, GCL System Integration, and Hansol Chemical, all of whom are competing on technical service depth and purity leadership.

Regulatory and Operational Hurdles

Despite the bullish outlook, the market faces constraints due to the exhaustive qualification cycles required by fabs. The transition to new chemical suppliers can take months of validation to ensure no risk of equipment corrosion or wafer defects. Furthermore, the safe handling and transportation of high-concentration oxidizers involve complex regulatory compliance that increases operational overhead for global distributors.

Future Outlook: Integration with AI and Green Chemistry

Looking toward 2030 and beyond, the market is expected to integrate more "smart" manufacturing features. Technology trends such as closed-loop metering and in-situ concentration monitoring are helping fabs improve process repeatability. Additionally, a growing emphasis on green chemistry is prompting suppliers to develop more sustainable production routes to meet the ESG requirements of global electronics OEMs.

Similar Industry Reports

Hydrogen Peroxide Stabilizers Market

https://www.futuremarketinsights.com/reports/hydrogen-peroxide-stabilizers-market

Hydrogen Peroxide Market

https://www.futuremarketinsights.com/reports/hydrogen-peroxide-market

Vaporized Hydrogen Peroxide Sterilization System Market

https://www.futuremarketinsights.com/reports/vaporized-hydrogen-peroxide-sterilization-system-market

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.